Condition Monitoring

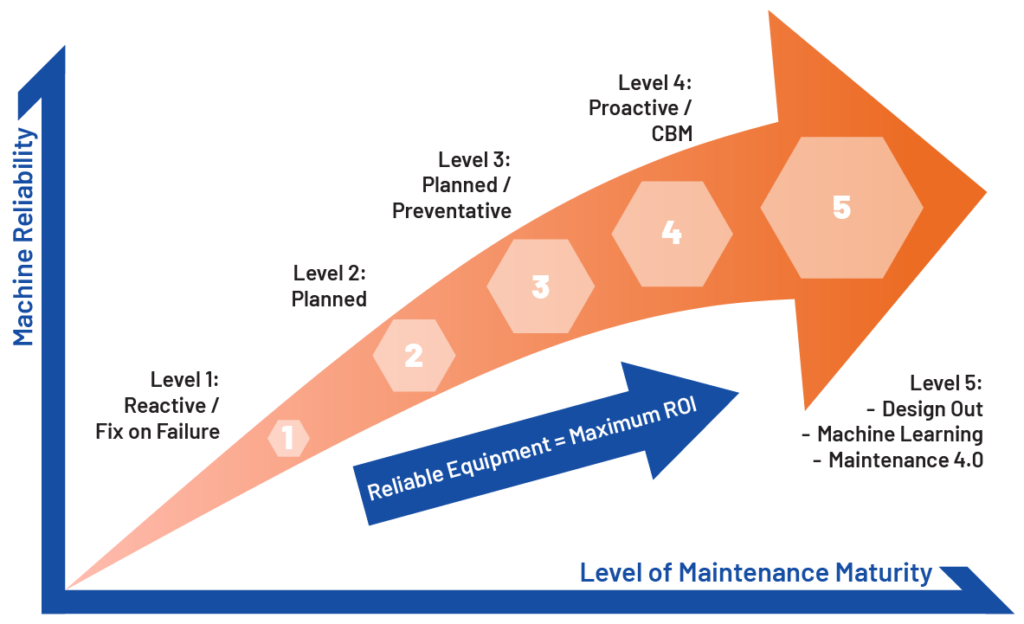

Enabling Condition Based / Predictive Maintenance Strategies

“Undetected failure is not an option!” ….early fault detection and failure avoidance using the most efficient monitoring tools; route-based or fixed systems.

We aim to detect all faults early enough to provide remedial advice to avoid machine failure therefore reducing maintenance costs, downtime and improving productivity and availability.

Condition Monitoring Techniques

Vibration Analysis

For a significant majority of machines and failure modes, Vibration Analysis is the most effective means of early fault detection.

Using the DigiVibe equipment and software, the focus is on detecting faults before they become failures.

Our high-end capabilities include integrating ODS (Operating Deflection Shapes), 3D Waterfall, FFT, Phase, Orbits, Bide, Cross Power Spectrum, Frequency Response, and Coherence into our fault identification process.

Benefits of using Intel-Sense for VA include;

- Quality & Consistency; Delivering condition monitoring processes in accordance with ISO 17359 processes

- Transparency; open access to data and reports

- Flexibility; Data is owned by our clients, not us. Programs are flexible as sites develop and faults eradicated

- Remote support

- Visibility & site buy-in; high level of communications, case studies, good-news stories etc.

Fixed and Wireless Based Systems

As official distributors for the best fixed and wireless equipment in the world, we are able to specify and install systems to monitor;

- Vibration

- Power

- Temperature

- Speed

- Oil Condition

- Process inputs

Remote Analysis

With consultants trained to the highest level in Condition Monitoring (VA4) and state of the art & secure online data management; we are able to provide best-in-class analysis and machine health recommendations 24/7/365, to any site or vessel, anywhere in the world.

Ultrasound

Ultrasound is a key element of an integrated CM strategy; giving the ability for early detection of mechanical and electrical faults.

Our SDT Ultrasound detectors sense high-frequency signals and convert them into corresponding audible sounds while maintaining their original characteristics and qualities, providing the ability to predict failures, control energy costs and improve product quality.

Oil Analysis

Intel-Sense provide you with on-site analysis kits to enable you to achieve actionable instant results.