At Intel-Sense Hellas, we believe that sustainability is not just an optional add-on but a fundamental necessity for the future of industrial operations.

Why? Because we recognize that our planet’s resources are finite, and every action we take today shapes the world we leave for tomorrow. In machinery condition monitoring, this means innovating beyond traditional practices to reduce waste, conserve energy, and minimize environmental impact. Our commitment to sustainability drives us to partner with leading-edge companies like Erbessd-Instruments, providing wireless sensor solutions that ensure efficient and reliable operations while championing the health of our environment. By prioritizing sustainable practices, we aim to not only enhance the performance of industrial systems but also to contribute positively to the global effort of preserving our planet for future generations.

The Traditional Approach: Sustainability Issues with Wired Sensors

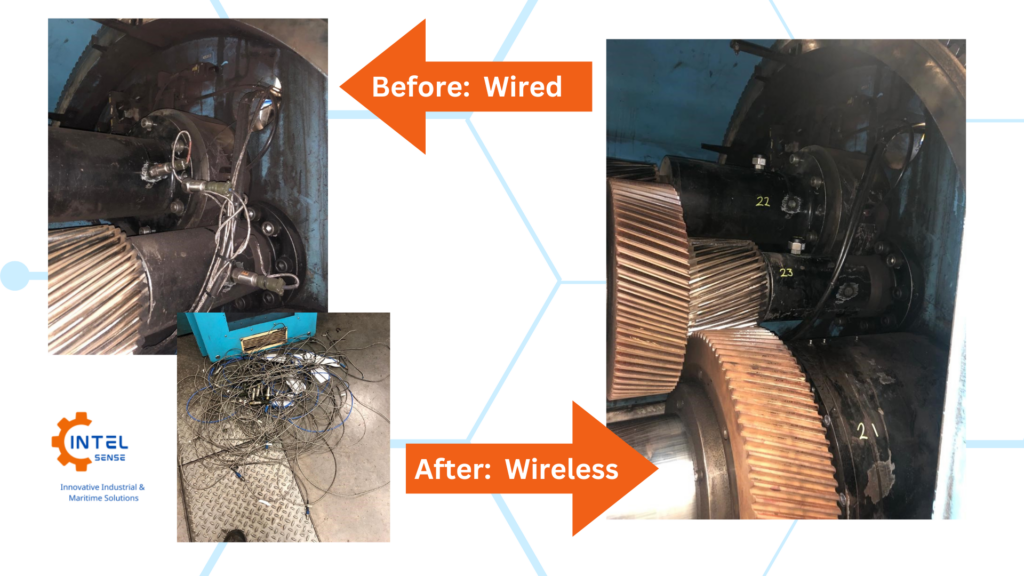

Historically, condition monitoring has relied heavily on wired sensors. While these sensors have been effective in capturing essential data, they come with several sustainability challenges:

1. Resource Waste: The extensive use of cables and connectors requires significant material resources. Over time, wear and tear necessitate frequent replacements, leading to increased waste.

2. Energy Inefficiency: Wired sensors often require continuous power supply, contributing to higher energy consumption. Additionally, the installation and maintenance processes can be energy-intensive (as well as costly).

3. Maintenance Challenges: Regular maintenance and repairs of cables and connectors are labor-intensive and resource-draining. Broken or damaged cables lead to sensor failures, causing unplanned downtime and operational inefficiencies.

4. Environmental Impact: The manufacturing, transportation, and disposal of cables contribute to the environmental footprint. Electronic waste from discarded cables and connectors adds to the growing problem of e-waste.

Going Greener: Sustainable Advantages of Wireless Sensors

Wireless sensors, such as those provided by Erbessd-Instruments, offer a progressive solution to the limitations posed by wired systems, particularly in terms of sustainability:

1. Reduced Resource Consumption: Wireless sensors eliminate the need for extensive cabling, reducing the demand for raw materials and minimizing waste. This leads to a significant reduction in the environmental footprint associated with sensor installations.

2. Energy Efficiency: Wireless sensors often operate on low-power technologies and can be designed to conserve energy through efficient data transmission protocols. Many wireless sensors come with long-lasting batteries, further enhancing their energy efficiency. The Erbessd-Instruments’ sensor batteries have proven longevity of 5 years or more.

3. Lower Maintenance Requirements: Without cables to maintain or replace, the maintenance demands for wireless sensors are considerably lower. This translates to less downtime and reduced resource usage for repairs and replacements.

4. Flexible and Optimal Placement: Wireless sensors can be installed in optimal positions without being constrained by cable lengths, tolerances or the need to accommodate moving parts. This ensures more accurate and comprehensive monitoring, leading to more efficient operations and lower energy consumption.

5. Enhanced Scalability: Adding new sensors or expanding the monitoring system is straightforward with wireless technology. This scalability supports the integration of more sensors as needed without the environmental impact of additional cabling.

6. Data Accessibility and Proactive Maintenance: Wireless sensors can seamlessly integrate with modern data management systems, allowing for real-time data access and remote monitoring. This empowers engineering teams to perform proactive maintenance, preventing issues before they cause significant downtime or environmental harm.

Sustainability at the Core of Intel-Sense Hellas and Erbessd-Instruments Partnership

At Intel-Sense Hellas, we are dedicated to providing innovative solutions that enhance the reliability, efficiency, and sustainability of industrial operations. Our collaboration with Erbessd-Instruments allows us to offer highly developed wireless sensors that are specifically designed to meet the demands of modern industrial environments.

Erbessd-Instruments’ wireless sensors are renowned for their durability, precision, and ease of integration. They are equipped with advanced features such as:

- High-Accuracy Data Acquisition: Capturing precise vibration, temperature, and other critical parameters.

- Robust Design: Built to withstand extreme conditions and ensure long-term reliability.

- Live Monitoring: Facilitating proactive maintenance and early detection of potential issues.

The shift from wired to wireless sensors represents a significant advancement in the field of machine condition monitoring. For industries in Greece and beyond, embracing this technology means not only reducing downtime and lowering maintenance costs but also enhancing sustainability. Wireless sensors offer a more reliable and eco-friendly solution, promoting efficient operations and reducing the environmental impact of industrial activities.

At Intel-Sense Hellas, we are at the forefront of this greener technological evolution , offering solutions that not only meet but exceed the demands of modern industrial environments. By integrating Erbessd-Instruments’ wireless sensors into your condition monitoring systems, you can ensure that your machinery operates at peak performance, safeguarding your productivity and profitability while contributing to a more sustainable industrial practice.

Explore our range of wireless sensors and discover how Intel-Sense Hellas can help you transform your condition monitoring strategy for a greener future.