The global market in 2021 for marine lubricants was over $6billion and increasing. . Unplanned maintenance, downtime, and meeting sustainability targets are costly challenges as Marine Engineering Procurement Managers and Marine Reliability Engineers look to ensure the optimum performance and longevity of marine engines and hydraulic systems.. Tan Delta Systems provides real-time oil quality monitoring technology, offering significant benefits to marine operations. In utilizing Tan Delta Systems, oil life is extended, producing significant savings.

Real-Time Oil Monitoring Benefits

Tan Delta’s Full Spectrum Holistic (FSH) monitoring technology ensures any changes in oil quality are instantly detected, accurately measured, and reported. This proactive approach helps in:

⦁ Preventing Unplanned Maintenance:

By predicting oil-related machine failures before they occur, Tan Delta sensors reduce costly unplanned maintenance and downtime.

⦁ Enhancing Maintenance Planning

Accurate oil condition data allows for predictive maintenance, ensuring problems are addressed before they lead to significant damage or operational interruptions.

⦁ Meeting ESG and CSR Targets

Reduced oil usage and minimized environmental impact align with corporate sustainability goals.

Dynamic Maintenance Optimization (DMO)

Tan Delta’s Dynamic Maintenance Optimisation (DMO) technology operates on a user-friendly traffic light system:

⦁ Green: Equipment is running optimally.

⦁ Yellow: Equipment is due for an oil change.

⦁ Red: Immediate attention is needed.

This system simplifies maintenance decisions, ensuring that marine vessels operate efficiently and safely.

Case Study Insights

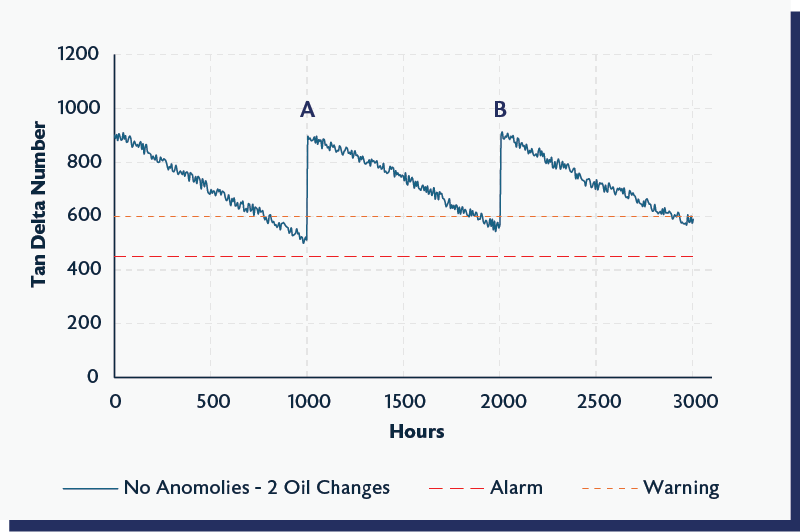

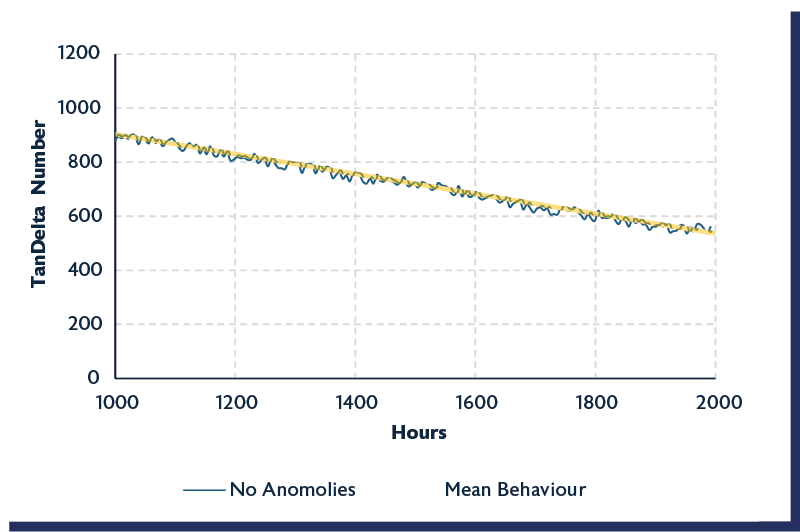

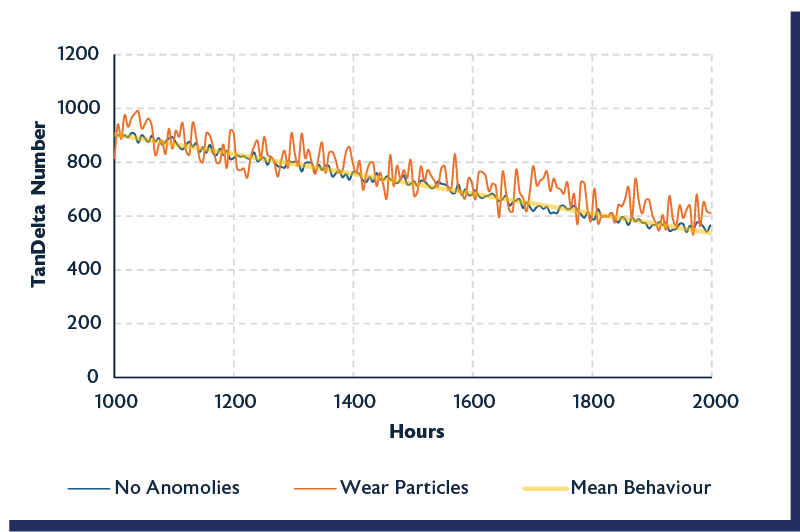

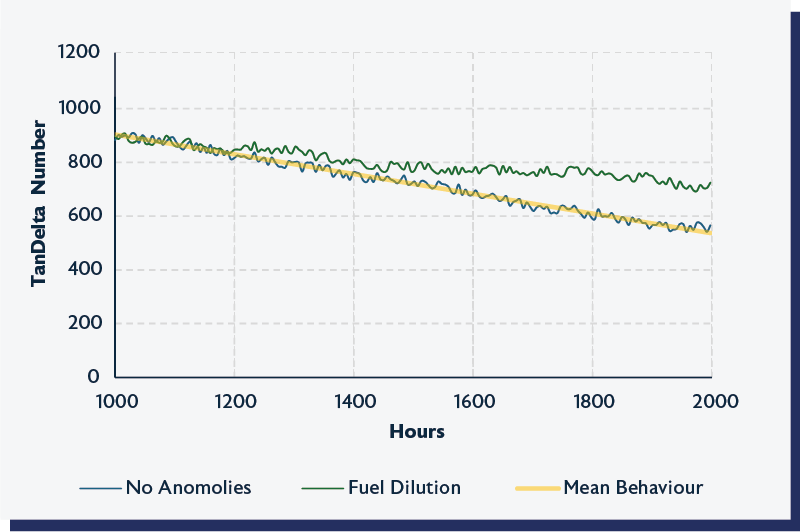

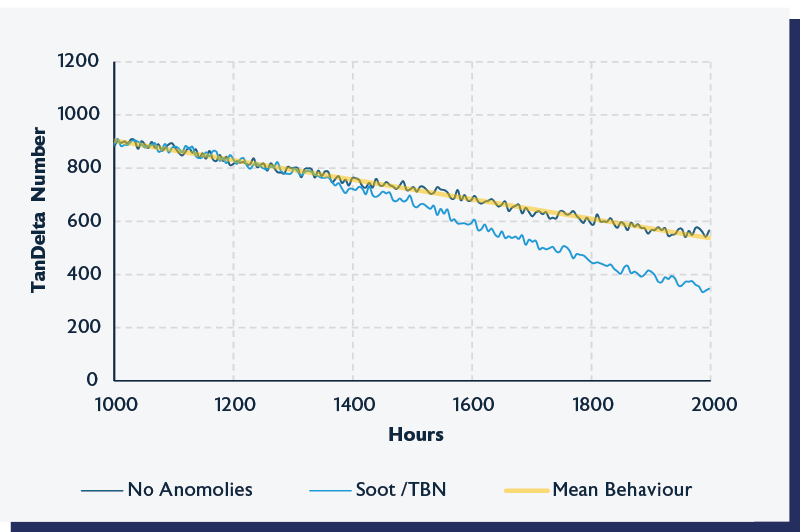

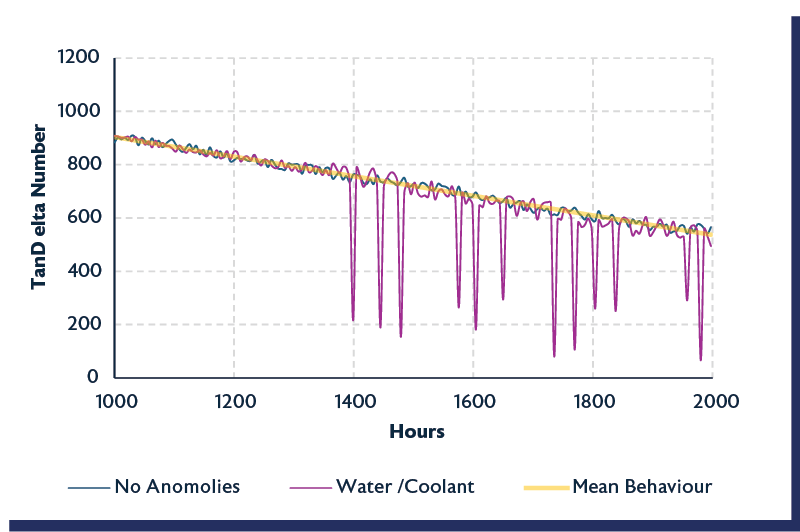

Graphs in the report illustrate how oil condition degrades over time. Real-time data identifies contaminants such as wear particles, fuel dilution, water/coolant ingress, and soot contamination. Each contaminant has distinct patterns:

Oil Degradation Trends: Typical degradation patterns indicate when oil changes are needed. Deviations from these patterns can signal faults or anomalies.

Wear Particles: Increased size and frequency of condition fluctuations.

Fuel Dilution: Lower degradation rate or unexpected increase in Tan Delta Number.

Water/Coolant Ingress: Intermittent spikes in low TDN, often coinciding with engine restarts.

Soot/TBN Reduction: Faster reduction in TDN over time.

For marine operations, Tan Delta’s real-time oil quality monitoring technology offers unparalleled advantages in maintaining the health and efficiency of engines and hydraulic systems. By integrating this technology, Marine Engineering Procurement Managers can achieve substantial cost savings, reduce unplanned maintenance, and support sustainability initiatives.

For marine engineers seeking to enhance their fleet’s efficiency and reliability, Intel-Sense Hellas offers cutting-edge solutions in online continuous condition monitoring and mobile oil condition monitoring. Contact us today to discover how our products and expertise can optimize your vessel operations and ensure peak performance.