Just a minor imbalance can lead to component failure.

Causes of Turbocharger Imbalance

Imbalance in turbocharger Shaft & Wheel assemblies can arise from several factors:

Wear and Tear: Continuous operation at high speeds and temperatures causes natural wear on bearings, seals, and blades. Over time, this wear can result in weight discrepancies within the impeller, leading to imbalance.

Corrosion and Fouling: Exposure to harsh environments, can lead to corrosion of turbocharger components. Additionally, the build-up of contaminants such as soot and unburned fuel on the blades can create uneven weight distribution, exacerbating imbalance.

Manufacturing Defects: Even minor imperfections during the manufacturing process can cause imbalance. Precision manufacturing and quality control are critical in preventing such issues.

Improper Maintenance: Incorrect assembly during maintenance procedures, use of improper tools, or neglecting regular cleaning and inspection can all lead to misalignment and imbalance of the impeller.

Turbo Trouble: The Hidden Dangers of Unbalance

Imbalance in a turbocharger leads to increased vibrations that propagate through the engine, causing further wear and potential damage to other components. This imbalance results in reduced efficiency, as the unbalanced turbocharger operates less efficiently, decreasing engine performance and increasing fuel consumption. Additionally, the vibrations and misalignment from the imbalance cause accelerated wear of bearings and seals, which increases maintenance needs and costs. In severe cases, the imbalance can lead to catastrophic failure of the turbocharger. Such a failure not only results in significant engine damage and operational downtime but also poses safety risks and environmental issues.

The combination of increased vibrations, reduced efficiency, accelerated wear, and potential failures underscores the critical importance of maintaining a balanced turbocharger for optimal engine performance and longevity.

Addressing Turbocharger Imbalance

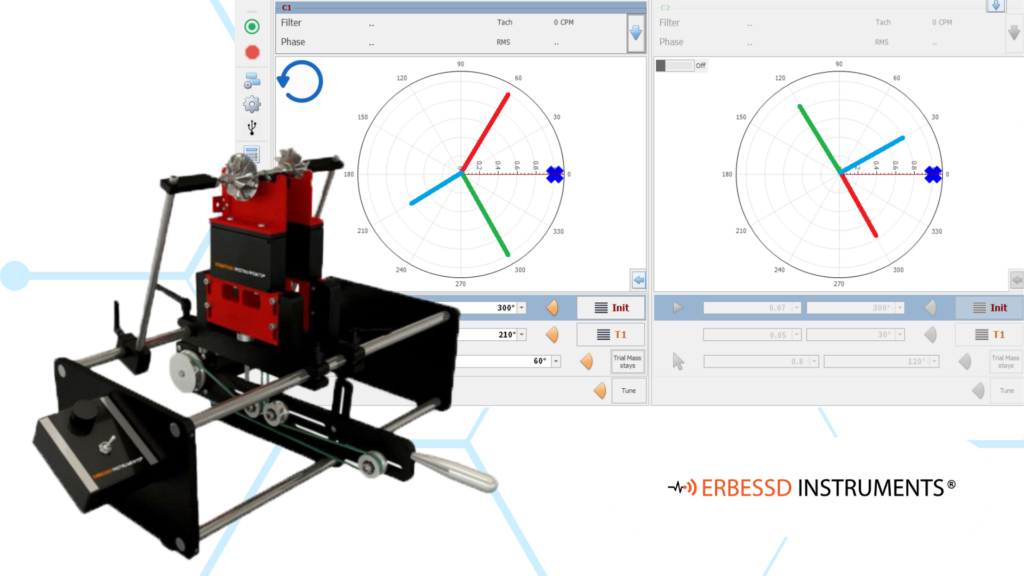

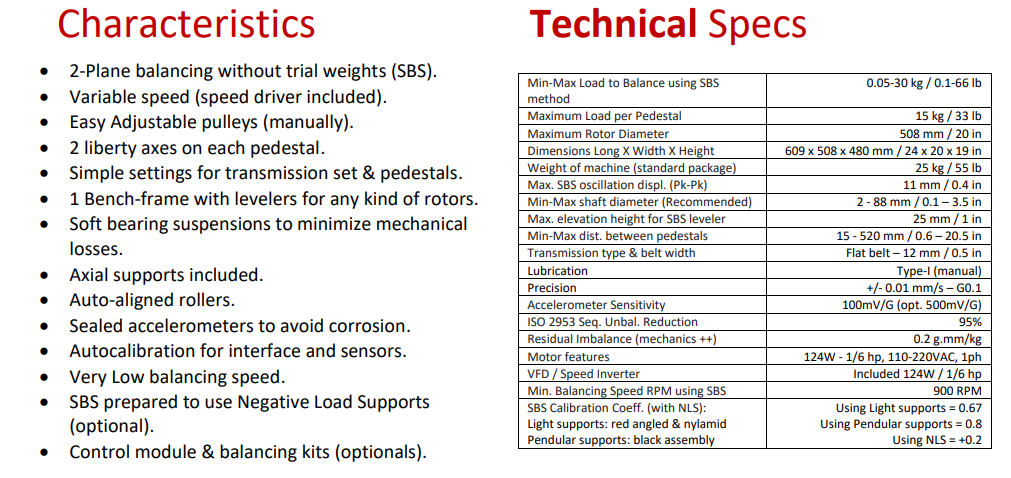

Once detected, addressing turbo imbalance requires precise and effective solutions to restore balance and prevent future issues. The use of advanced balancing machines, such as the EI-30 Balancing Machine by Erbessd-Instruments, can be instrumental in this process.

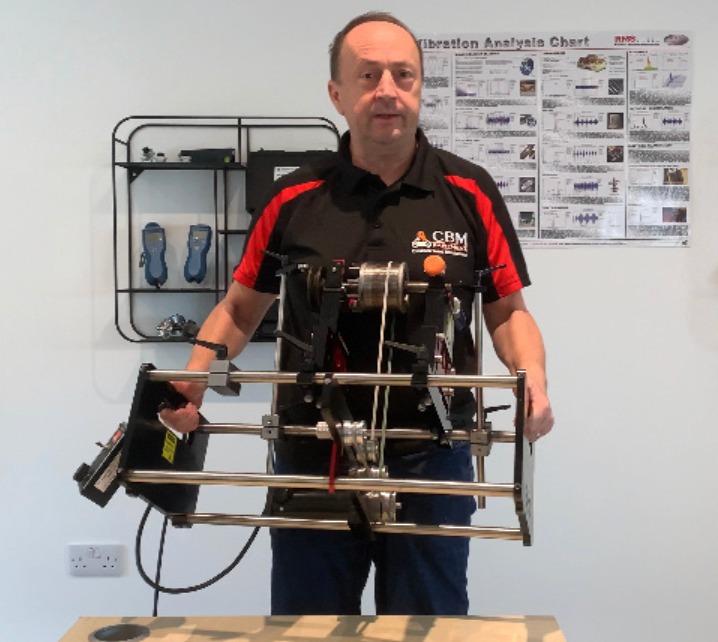

Shafts come in all shapes and sizes, so to maximise your return on investment, the EI-30 Balancing Machine offers you versatility as it is non-shaft specific. It has a DC engine, variable speed control and adjustable pulley for the prevention and resolution of turbocharger impeller imbalance issues. It’s also portable so you can use it anywhere, any place, any time!

Photo credit CBM Partners Ltd, UK, demonstration of portability of Erbessd-Instruments’ EI-30 Balancing Machine

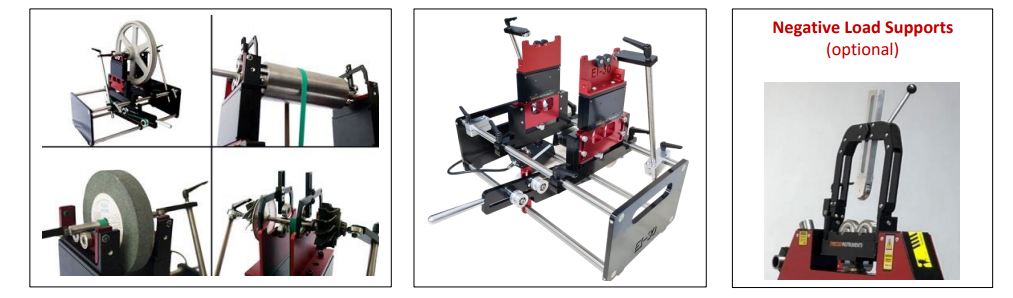

The EI-30 Balancing Machine: A Technical Overview

High-Precision Balancing

The EI-30 Balancing Machine offers a range of benefits designed to enhance precision, ease of use, and safety in balancing operations. Its high-precision balancing capability ensures accuracy up to 0.01 grams, allowing even the smallest imbalances to be corrected efficiently. With a variable speed range between 1,000 and 5,000 RPM, the machine can perform balancing tasks effectively by allowing the rotor to spin around its center of gravity, rather than its geometric center. The inclusion of dual-plane balancing without the need for trial weights further enhances its precision.

To minimize mechanical losses, the EI-30 features soft bearing suspensions, and it is also equipped with sealed accelerometers to prevent corrosion. Universal adapters and easily adjustable pulleys offer flexibility in handling different rotors, while the modular design allows for easy upgrades and customization. Automatic calibration ensures consistent accuracy and repeatability, and the machine supports various correction methods, including adding or removing material from the rotor.

The two liberty axes on each pedestal simplify the settings for the transmission set and pedestals, while the DigivibeMX M10 software provides detailed vibration and frequency analysis, helping to pinpoint the exact sources of imbalance. This software also allows for logging data and generating detailed reports, which are invaluable for maintenance records.

The machine’s touchscreen interface makes setup and operation straightforward, catering to technicians with varying levels of experience.

Safety features such as protective covers and emergency stop functions are also included, and the EI-30 meets industry standards for balancing equipment, ensuring compliance and reliability.

Implementing a Preventive Maintenance Program

A good preventive maintenance program should include scheduled inspections, condition monitoring, data analysis and training and education. Routine balancing, using the EI-30 for turbocharger impellers, especially after repairs or significant operational periods can mitigate the risks associated with turbocharger imbalance and ensure the optimal performance of their machines. Investing in precision balancing not only enhances the longevity and efficiency of turbochargers but also contributes to the overall reliability and profitability of industrial operations.